Metal Stamping Services

Are you ready to Tool Up, and Reduce Cost?

At Ameristar Mfg. we can guide you through the process of creating one hundred pieces per year, to one million. Ameristar Mfg. has the ability to produce parts without any of these tooling options for lower quantities, and when you’re ready we are here to help you decide which option best fits cost reduction requirements, and total investment.

If want to learn more about our metal stamping services see the details below. To find out about our other high quality and affordable services, please contact AmeriStar today.

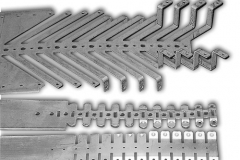

Stage/Form Tooling

EST. COST $

Form/Stage Tooling is utilized to decrease the production time for bending metal. This is perhaps the cheapest form of metal stamping in which we utilize a Punch Press instead of a Press Brake to bend tabs, flanges, or Offsets. This tooling is a great option for customers looking to achieve part cost reductions without large tooling cost. This is achieved by blanking a part by laser or turret cutting and then forming with hard tooling. Estimated cost for this tooling can be as little as $250-500 and it can have substantial savings for customers looking to reduce part cost with limited tooling expenditures.

Compound Tooling

EST. COST $$

If blanking your part out by utilizing Laser and or Turret Cutting is too expensive the next step up would be a Compound Tool. With a compound tool we will Stamp the entire flat layout of your part with every rotation of our punch press. This is the fastest way to produce a flat layout, and it can be combined with Form Tooling as a secondary option if Progressive Tooling options don’t make financial sense. This tooling can vary in cost depending on thickness and size, but could be as little as $500 to $5,000 depending on complexity.

Progressive Tooling

EST. COST $$$

Progressive Tooling combines forming and blanking into one process. Generally a Coil or Sheet Stock will be loaded into one side of the punch press. When the part comes out it is complete including forms, coining, offsets, and other features as required. This option is best for higher volumes. This production tooling will yield the cheapest part cost mostly due to reduced handling and labor, and higher efficiencies. Tooling can vary in cost depending on the complexity and features of the part. A general range for a simple part could be as low as $2,500, whereas an extremely complex part could vary from $25,000 to $100,000 or more.

| Production Method | Punch Press Turret Press Shearing Coining Compound Die Compression Continuous / Progressive Tooling Forming Perforated Metal Progressive Die Strip Feed |

| Part Length | Max 24 in |

| Part Width | Max 50 in |

| Part Thickness | Max .500 in |

| Tolerance (+/-) | .005 in |

| Production Capabilities | Small Parts Intricate Complex |

| Stamping Features | Coated Countersunk Embossed Enameled Flat Heat Treated Numbering Ornamental Shape Critical Strain Relief Surface Critical Tapped Threaded |

| Press Rating | 45-200 tons |

| Materials | Aluminum Stainless Steel Cold Rolled Steel Hot Rolled Steel Brass Copper Titanium Galvanized Galvannealed Nickel Alloys Inconel Monel Mica Plastic |

| Stamping Product | Electronic Chassis Electronic Assembly Electronic Components Cable Housings Display Components Fuel Station Panels Special Brackets Mounting Plates |

| Additional Services Provided | Heat Treating Plating Finishing Powder Coating Assembly Kitting Painting Tooling Anodizing Annealing Number Stamping (Rubber Ink and Metal) E-Coat Stress Relieving Vibratory Bowl Deburring Tumbling Assembly Packaging Rivet Inserting Welding |

| Production Volume | Prototype Runs to Full Production Quantities |

| Industry Focus | OEM Military Electronics Agriculture Recreation Vehicles Lighting Automotive Printers Boating Aviation Construction Vending Medical Defense |

| Industry Standards | ISO 9001:2008 |

| File Formats | AutoCAD IGES DXF MasterCAM Images |