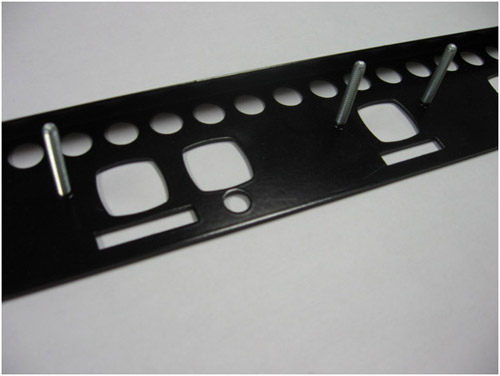

Metal Stamping of Cold Rolled Steel Keyboard Mounting Bracket for the Music Industry

An entertainment company approached AmeriStar to manufacture a mounting bracket for a high-end keyboard. We first turret stamped the .100″ thick cold rolled steel. As each sheet came off the turret press, it was deburred. Then the bracket’s inserts were press fit into position. The mounting brackets were then painted with a black powder coat. The hardware was inserted perfectly flush with the part to prevent showing through the customers applied overlay.

Each of the brackets was individually bubble wrapped and taped to ensure the parts were not scratched due to part-to-part contact. Every order included 200 pieces and was completed and shipped to the client’s Chicago location within 4 weeks.

For more information about this stamping and pressing project, please see the details below. To learn about our other outstanding services, contact AmeriStar today.

Metal Stamping of Cold Rolled Steel Project Highlights

| Product Name | Keyboard Mounting Bracket |

| Project Scope |

|

| Capabilities Applied/Processes |

|

| Tightest Tolerance | +/-.005″ |

| Material Type | CRS (cold rolled steel) and Inserts |

| Material Thickness | .100″ thick CRS |

| Product Length | Up to 8 foot long pieces |

| Product Width | Up to 4 foot wide |

| Material Finish | Black Powder Coating |

| Packaging | Each panel, so as to insure the very pristine cosmetic nature of the part is individually bubble wrapped and taped so as to insure no part-to-part contact that might scratch each part |

| Secondary Operations Applied | Powder Coating |

| Industry for Use | Music/Entertainment |

| Tooling Cost | $200 |

| Standards Met | Customer supplied design and prints |

| Volume | 200 pieces per order |

| Delivery Time | 4 weeks |

| Delivery Location | Chicago, IL |