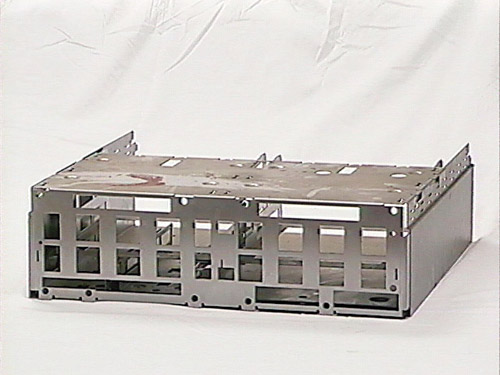

Turret Stamping of Electronic Cabinets and Enclosures for the Electronics Industry

AmeriStar provides many different styles and shapes of electronics enclosures such as this one. We first stamped the sheet metal, and then we press braked formed the metal into a 3-dimensional shape. The cabinets and enclosures’ nuts and studs were then press fit or welded into position.

The type of material used in each cabinet or enclosure differed based on their intended use. Some were made of cold rolled or stainless steel, while others were made from aluminum or galvanized steel. The items’ thickness and size also varied according to use, along with the type of welding used to attach any parts.

The orders, which were as small as 50 pieces and as large as 5000 pieces, were completed and delivered in 4 weeks to the client’s Denver location.

For more information about this project, please see the details below. If you want to learn about our other services, please contact AmeriStar.

Turret Stamping Project Highlights

| Product Name | Electronic Cabinets and Enclosures |

| Project Scope |

|

| Capabilities Applied/Processes |

|

| Tightest Tolerance | +/-.005″ |

| Material Type | Cold Rolled Steel or Stainless Steel or Aluminum or Galvanized |

| Material Thickness | .250″ thick Steel Sheet Stock |

| Product Length | Up to 12 foot long panels |

| Product Width | From 6″ wide up to 6 feet wide |

| Secondary Operations Applied | Inserting of hardware (Autosert Equipment) |

| Industry for Use | Electronics/Electrical |

| Tooling Cost | $250 – $500 |

| Standards Met | Customer supplied design and prints |

| Volume | From 50 piece orders to 5000 pieces per order |

| Delivery Time | 4 weeks |

| Delivery Location | Denver, CO |